Make a Joyful Noise

June 7th, 2011Get Knock on Door From Joyful Cops

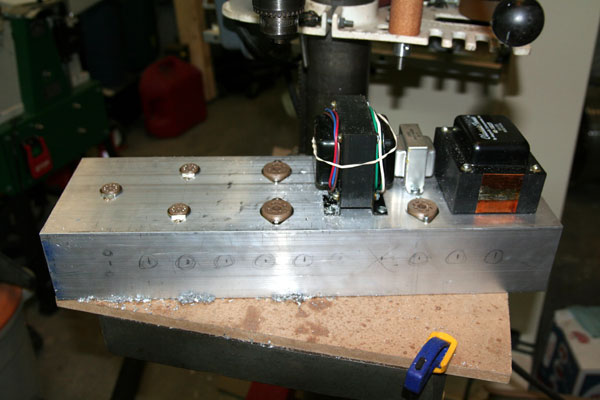

Here’s what I got so far:

I had a lot of fun making tube socket holes in 3/16″ aluminum. I had to use a 1 3/16″ hole saw for the big tubes and a 3/4″ Forstner bit for the small ones. I should buy stock in WD40; I used so much to keep the bits from binding.

The stuff on top will be held down with wood screws. There is no need for nuts when the metal is this thick.

This is extremely cool. Can’t wait to turn it on.

June 8th, 2011 at 9:24 AM

WD-40 will work, but real cutting oil for aluminum is MUCH better. Seriously, there’s a BIG difference.

And don’t do wood screws. Drill and tap the holes in the aluminum. Much more workmanlike and elegant job. You’d be proud…

June 8th, 2011 at 7:48 PM

A lot of old time machinists used kerosene as cutting fluid for aluminum. Might be worth a try.

Cajun’s right: aluminum’s easy to tap and worth the effort.

Keep on keepin’ on baby.

Lee

June 8th, 2011 at 8:06 PM

I appreciate the help, but I didn’t pull WD40 out of a hat. It was recommended by experts. I have a different fluid for threading aluminum, and two more fluids for steel.

.

The results with WD40 are excellent, and you can get it by the gallon at Home Depot, so even if the other stuff is better, I don’t have any reason to switch.

.

As for kerosene, I am told that’s the main ingredient of WD40. Don’t know if it’s true.

June 9th, 2011 at 2:05 PM

Maybe I should try WD-40 myself instead of dispensing “pearls of wisdom,” over the internets, ha ha. I’ve been using 3-in-1 oil cause I have a big bottle of it handy and it seems to work fine.

Anyway, blah blah blah, enough of my advice. That’s a nice looking amp chassis, you should be proud.

Best,

Lee