Alfred, Bring me Another Brandy

May 24th, 2009And Have Burt Ward Wax the Batmobile

I can’t believe how much I rock. Check this out.

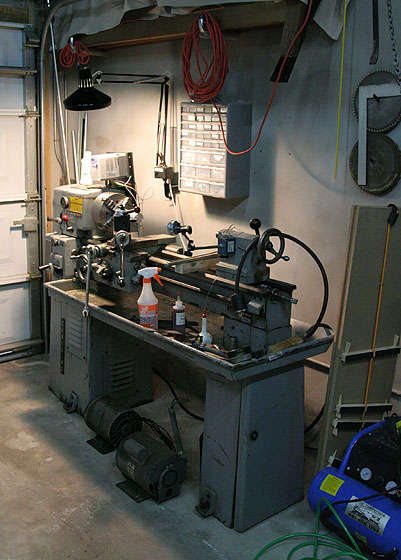

That’s the lathe, with a new old light installed, plus a 4-jaw chuck. And I added a couple of new wrenches. I think when you have a lathe, your best bet is to buy a couple of wrenches that fit the things you turn most often and just leave them where you can reach them. It beats running back and forth from the tool chest.

That light is from my old desk; the one I used when I was getting my bachelor’s degree. It was in a storage hole over a closet. Came in handy.

The light is attached to a piece of scrap I bolted to the wall. I had a 4″ section of 2″ by 3/16″ angle iron lying on the floor, so I drilled three holes in it and fastened it to the wall. Then I clamped the lamp base to it.

I also replaced the fine wheel on my bench grinder. Baldor ships these with fairly crappy wheels. It’s not that they’re cheap, although maybe they are. The quality is not the issue. The problem is that they’re not right for grinding lathe tools. I got an 80-grit aluminum oxide wheel from Enco, and I trued it (I think) with a silicon carbide stick. I’ll get one of those star wheel things if I can ever find a place that sells them AND has them in stock.

The spray bottle is WD40, from a Home Depot gallon jug.

I have replaced the worthless gear selection lever the lathe came with, and that white thing on the headstock is Moly-Dee. It is conceivable that I could turn something, if I knew how.

The 4-jaw chuck is mysterious. I tried to true up that piece of aluminum in it, but the weight makes it difficult. If you loosen one jaw so you can tighten another and move the aluminum, the aluminum likes to flop downward at the end and make things worse. Getting it within three or four thousandths of straight seems relatively easy, but I believe you’re supposed to be able to eliminate measurable error with one of these chucks.

I have the electrical parts to pretty up the wiring and put it away. Maybe tomorrow. In the photo it looks like the wiring is near the spinning stuff, but it really isn’t.

This week the insulation for the garage doors arrives. It’s very nice in the garage already, but insulation will probably make it even better.

I have to move the compressor to make room for the mill. That means running conduit over the rafters, about 14 feet off the ground. I can hardly wait! Maybe I should wait until my medical insurance kicks in.

May 24th, 2009 at 7:40 PM

“This week the insulation for the garage doors arrives. It’s very nice in the garage already, but insulation will probably make it even better.”

…you’re quite welcome Brother Steve…

May 24th, 2009 at 7:50 PM

I remember that light.

May 24th, 2009 at 8:59 PM

Remember that when installing conduit in high places it is not recommended to stand in the bucket of your Bobcat using it as a man-lift. At least that is what the little pictograph things show stuck on the side next to the lift arms.

.

It is however much easier and convenient if you have a skilled operator. Not like the blind guy that kept running us into the ceiling onve when working on a workshop for the blind. Long story, best over beer.

May 24th, 2009 at 11:23 PM

Don’t loosen the chuck so much, once you get it close. Think of it more as adjusting and balancing the tension in the screws, rather than moving the workpiece. Work one axis and then the other; don’t loosen the axis across the direction you want to move, at all. Once you’re really close, don’t loosen anything. Finish the adjustment by tightening only.

May 25th, 2009 at 10:37 AM

You may consider a plastic back-splash of some kind at this point in your setup, as any liquid lube you put on the chuck will fling against your wall, then run down to the floor. its easy to do now before the mess is made. just thinking out loud…

bob

May 25th, 2009 at 12:41 PM

Steve,

Here’s a procedure for adjusting parts in a 4-jaw lathe chuck:

http://bbs.homeshopmachinist.net/showthread.php?t=22535&highlight=adjust+4+jaw+chuck

here’s how to center a piece of square stock:

http://bbs.homeshopmachinist.net/showthread.php?t=20974

the second thread has a post by John Stevenson that’s especially good, he doesn’t even use an indicator.

May 25th, 2009 at 2:25 PM

Once you get the hang of it, it goes quick.

Then you start lusting after 6 jaw Adjust-trus

May 25th, 2009 at 9:42 PM

Leo, my son used to work at a Hobby Lobby warehouse, and said one of the first training things he got was a video on “Why I should not ride on the conveyor belt.”

I have a set of wrenches that stay on the loading bench; got an inexpensive set of combo wrenches, picked out the ones that fit the nuts and dies, and that way I never have to go to the tool box and dig for them.

May 26th, 2009 at 10:38 AM

The Tool Hanger pegboard goes to the right of the wall cabinet with the little drawers. tape-lines are optional.

Don’t listen to Bob. It’s not a real shop if it doesn’t have fluid stains on the wall and pig mats under the lathe. Sure, it’s better, but…