Post About a Post

May 18th, 2009Gonzo Machinist Strikes Again

Raise your hand if you are one of the idiots who took me seriously when I said I was going to quit trying to mill the base for my tool post.

SHAME ON YOU. You KNOW I don’t have any common sense.

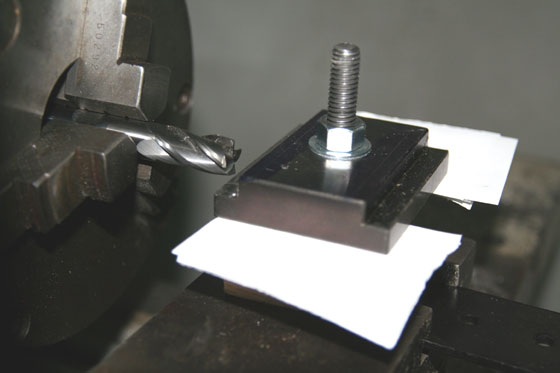

Here is the jig I came up with.

I have one tool which I am actually capable of using to make precision cuts, so I used it. I refer to the table saw. I cut two pieces of red oak a few thousandths over an inch in depth. I stuck them under the base. I enlarged a hole in an old piece of steel scrap, ran a bolt through it, and put it in the compound with the bolt pointing upward. I dropped the base over the bolt and added a washer and nut. Then I used a feeler gauge to figure out how many paper shims I needed under the base to get it to the right height. The base was too high as well as too wide, so I had to use the side of the cutter, not just the end.

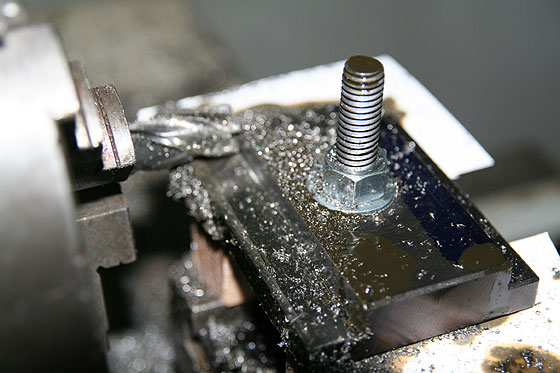

Base after a few passes:

I used a few drops of Moly-Dee (per pass) as cutting fluid, since that was all I had.

I was terrified the whole time. You can imagine what would happen if the cutter had managed to turn the base. I took tiny passes. Probably ten of them, plus a final climb-cut pass.

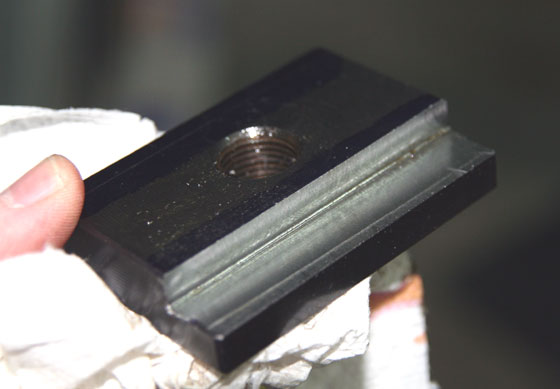

I know I did this all wrong, but the tools dictated the method. The result is fine. The major imperfections in the cut are from two sources: the sad effort I made the other day, and the sad efforts of the Chinese people who made the base.

I had to rest. It’s exhausting, focusing your attention on a cutter while making tiny, slow cuts.

I have three more cuts to make. Maybe I can find a way to use the dry cut saw to do the final ones. This doesn’t have to be pretty. It just has to fit in the slot in the compound.

If I succeed at this, I’ll have a functioning lathe!

May 18th, 2009 at 2:14 PM

nice.

Another bolt in the teeslot might have helped you feel more secure. Still, it seems to have worked ok.

keep going.

May 18th, 2009 at 2:53 PM

Steve,

Your work looks very good from here, good job!

I’d give you 2 cautions: Be sure that the hold-down bolt is tight and the piece is secure. It wouldn’t hurt to use Channel-Locks and try to twist it, it shouldn’t turn easily.

And, be very careful with climb cuts. The cutter will grab the part and suck the backlash out of the cross-slide screw, giving you the effect of very fast feed. This will usually break the cutter and screw up the part.

The same cautions apply to doing this job in a milling machine. And, no, you don’t want ball screws in your mill to eliminate backlash.

May 20th, 2009 at 3:35 AM

Looks good, small milling jobs like this are fine on the lathe. I made some t-nuts for my drill press in the same way.