I Made ANOTHER Thing!

February 14th, 2009Feast Your Unworthy Eyes

This has been a day of triumph mixed with slapstick.

I wanted to make a rack for my saw blades, so I went to Home Depot and bought a steel dowel to use to go through the arbors. I realize how ridiculous this is. I have started eyeing trash heaps very carefully as I drive, but I still have to buy metal all the time.

I cut pieces of the dowel to length, filed off the burrs, cleaned off the scale, polished up two pieces of scrap I intended to use for the bodies of two racks, turned on the gas for the welder, and realized…the valve had been open for about a week. I knew I would do this eventually. I need a checklist, and I probably need to have it tattooed on the back of my hand.

Okay, no welding today. This week I go to Airgas.

I moved on to another project. Luckily, I had picked up the materials while I was at Home Depot.

By way of background, I give you the sad tale of the planer sled. I bought a beautiful reconditioned Dewalt planer which turned out to be new. I made myself a planer sled so I would be able to put off buying a jointer. I ran wood through the planer on the sled. I discovered I got four inches of snipe, because it was very hard to support the outfeed well.

I went to Sawmill Creek and asked around, and I was referred to a device sold by a company called Lee Valley. It’s like a roller stand, but instead of one roller, which can steer the outfeed and make you crazy, it had a bunch of swiveled casters. They can’t steer the work. Brilliant. And I would have been thrilled to pay for one. But from the pictures, it looked like it would be impossible to get it close to the planer.

I realized I could make something similar, myself. That’s what I did today. It was a festival of testosterone, swearing, and tools. I got to use the bandsaw, table saw, impact driver, drill, and even the ROUTER!

I am just amazing. I don’t know how to bear it.

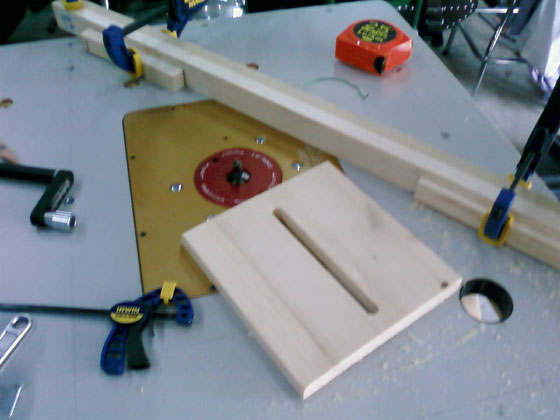

Here’s the router. This is really the first time I’ve used it since I put it in the table. I’ve screwed around with it a little, but until today I didn’t really accomplish anything. I needed a nice clean slot in this board, for a bolt to go through. I used stop blocks and plunge-routed the opening. That router plate is part of a lift, and the crank goes in the little hole with the small red dial around it. You crank to move the router up and down. I routed and cranked, moving the bit upward a tiny bit with every couple of passes. It’s amazing; when you get to the end, you can actually see the router bit and the new slot through the last layers of wood.

Here is the finished frame for the gadget. Now I can explain the idea. I wanted to put this on top of my sawhorses, and I wanted the height to be infinitely adjustable. Problem: the cross supports on the sawhorses are wide at the bottom and thin at the top. This means you can’t have a gadget with parallel sides that slides up and down on the support so you can clamp it at any height you like. The answer was to measure the angles of the support sides and make a frame that would rest flat against them. So I took the table saw and cut a slice off a two-by-four at 18 degrees. The slice will go behind the supports. The big part of the two-by-four will be part of the gadget’s frame. I’ll drill two holes in the support, and I’ll run a bolt through each slot and and the support. On the back side, I’ll have the slice, with holes for the bolts. Washers and wingnuts will go on the bolts. The slice will keep the washers flat against the wood surface.

Here are the casters. I can’t finish the gadget until I get the bolts, nuts, and washers. But it’s fairly clear that it will work. When I got the casters screwed it, I took the boards off the front, added Titebond III, and put them back together. I did that because I wanted to use three screws per board, but the slots make it likely that they would split the wood, which is softwood scrap.

The Lee Valley gadget has a metal plate on the “in” side, to steer stuff up onto the rollers. I’m sure I can fix something up that will do the same thing. They really need to make a version like the one I made. I would have bought it in a heartbeat.

The bandsaw is an amazing tool. If you can just remember to use it, it can do things that will surprise you. I’ll bet a metal bandsaw would be fantastic, if I were fabricating a lot of stuff. The plasma cutter is great for a lot of things, but it’s no bandsaw.

I can’t believe I made this thing, and that it was so easy. Looks pretty good, doesn’t it? A router will probably do more than any other tool to make your woodworking look professional. If you think about it, most of the crappy details that set an amateurish piece of woodworking apart can be blamed on the lack of a router.

Let’s not talk about the welding gas, okay? We’ll just let it be our secret.

February 14th, 2009 at 7:15 PM

Steve,

Don’t feel bad about leaving the gas valve open. We’ve all done it at least once, whether with the welder or a torch set. And, ALL of these devices seem to leak, enough that you’ll lose all your gas(es) in a day or 2 at most. <>

Nice looking job on the roller gadget! I’ll have to keep your design in mind for a future project.

February 14th, 2009 at 8:29 PM

I tell you what! You are king of the hill.

February 14th, 2009 at 9:07 PM

Nice job. Nice job of jigging up too.

You’ll find that you eventually figure out how to use those pieces as part of some other jig soon as well.

Get a piece of plywood as big as your biggest blade plus 2″. Use your router to make a handle in it. Put a carriage bolt through the middle and a big wingnut to hold the blades in place. Also a good way to carry them to the sharpener.

You can probably make it so it hooks uinder the skirt of your table saw.

February 14th, 2009 at 9:10 PM

Thanks, Og. That big open space under the saw table is crying out for a cabinet or something.

February 14th, 2009 at 10:53 PM

“Let’s not talk about the welding gas, okay? We’ll just let it be our secret.”

.

If you let me slide on the Radishes, I’ll forget about the gas…;-)

.

Myself, I gave up on gas…never seem to have it when I need it, so I stick with flux-wire and mild-steel, and I then put up with grinding off the splatter. Someday I may have a project that need to look pretty, but so far the flux-wire has been okay.

.

Good work on the router by the way.

February 16th, 2009 at 8:29 AM

I agree that the router is the basic tool that turns a rough piece into a finished piece. I have used my round-over bits a lot for this purpose. Nice to see pictures of your creativity kicking in again.