The Candy Store

February 13th, 2009I Want Sprinkles on That

I went and looked at some milling machines today. Here is my report.

The place I went to had several Series I Bridgeports, two Wells Indexes (“Indices”?), and a Powermatic Millrite. Their other machines were of no interest.

The Millrite needed to be put together; there were bits here and there. Most of it was in place. Just about every machine there had at least one piece that needed to be reinstalled.

I think I finally understand how backlash works. I keep reading about machines having this much or that much backlash, measured in thousandths of an inch. I always wondered how they arrived at the figures. I pictured someone crawling all over the machines with a feeler gauge.

Today I tried the dials or cranks or whatever they’re called on a bunch of machines. I mean the things that make the tables move. On all but two of the machines, the handles went through pretty large arcs before the tables started moving. And there are little graduations around the handles. I assume the free movement is backlash, and the graduations are thousandths, so it’s easy to measure the backlash accurately. I should have looked to be sure, I guess. I’m sure people will be glad to correct me.

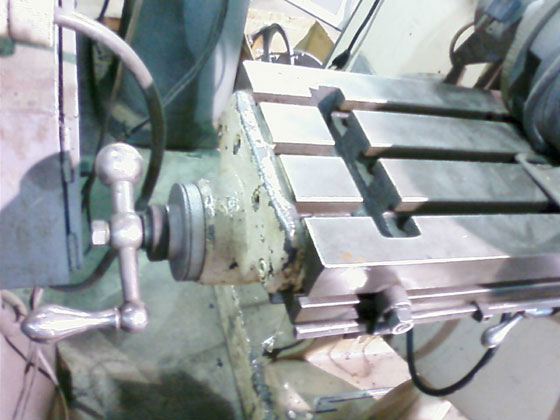

The Millrite appeared very solid. The paint was grey, and it looked like original paint, although I have seen Powermatic-green Millrites. Maybe I’m wrong. I could see no real problems with the table. Most of the machines had nicks and chips and so on. I didn’t see anything like that on the Millrite. And when I turned the handles, the table moved instantly. I lowered the quill, and it worked fine. I really don’t see any problems with it. Judging by the prices I’ve seen on Millrites, this thing is probably worth $1500. Unfortunately, they want $1950.

I was surprised to see how compact it was. I knew it would be smaller than a Bridgeport, but the difference is greater than I thought. I would say it takes up 50% more room than a 17″ drill press. It’s longer from back to front. And it’s not that tall; everything is right down where you can see it.

The Bridgeports were not so big they would not work well in my garage. The only one they had that looked like it was in good shape was a machine that had an old DRO and power feeds. Like the Millrite, it had a table that moved instantly when you turned the handles.

Here are some Millrite cellphone photos. Oddly, the metal looks better in photos than in real life, while the paint looks worse.

Here is the Bridgeport. It had chromed ways, and the scrapy marks were clearly visible. I thought this meant it was in better shape than the other mills, on which I could not see this stuff, but the guy who showed me the machines seemed to indicate that he felt the ways were worn. He said the power feeds and so on worked. The paint was horrible. It looks like someone applied house paint with a brush. One nice thing: variable speed.

They want $4750 for this thing. That is not going to work. I assume they would part with it for $4K, but that’s still pretty bad, unless I am seriously deceived by the mills I’ve seen online. I realize it has a lot of stuff on it, but that DRO appears to be Flintstone-era, and I am not very confident that it will last another month.

The mill’s serial number was 240xxx. I should look that up. I have read that some people make the mistake of checking the number on the head. I checked the number on the knee, which is the correct one.

The Millrite is really nice. It’s probably much newer, in terms of wear, than the Bridgeports. People don’t use Millrites for production, the way they do Bridgeports. But it’s small. And now that I’ve seen these things up close, I realize a Bridgeport is a viable option for me.

Of course, if I can get them to deal on the Millrite, and I can clean it up and make it beautiful, I should be able to resell it eventually for about what I’d pay. And I have to say, it looks like a sweet machine. Fits in a garage nicely, and the size makes it easy to reach everything. The pulleys are a bummer. A VFD would reduce the misery, but I’d have to shell out maybe two-fifty for a little one plus a motor.

A Wells Index would be a smart buy. I should go back and look them over more carefully. They run cheaper than Bridgeports, and they’re just as good, and the company is alive and eager to give good service. But it’s a bigger machine.

Delivery is not a problem. They have a guy who does it for 80 bucks an hour, so figure $240 with the obligatory super-slow pace of a savvy hourly worker. If he’s honest, $120.

I also looked at their Clausing lathe. They have a 12″ 1982 job that would fit beside a wall of my garage. Not very pretty, however, and I have read some unflattering things about Clausing lathes.

This was a fun trip. I have to figure out what to do now. The white Bridgeport is probably a good machine, but look what I can have in my garage for $1857 plus a grand for shipping: CLICK. Granted, it’s not a variable speed machine, and it doesn’t have a DRO, but it appears to be in much better condition, and those other things can be snapped up as deals become available.

It will be nice to have milling and drilling capability, and it will be even nicer to be able to turn things. Once I have a mill and a lathe, I should be able to consider my shop fundamentally complete. Other stuff will come later, to be sure, but I can’t think of any other big items I’ll need. I’ll be able to cut, shape and join wood and metal in enough ways to get just about any job done.

Fun sign at M&M Discount Liquors, which I saw on the way home: “OBAMA’S SECRET PLAN TO FIX ECONOMIC CRACKS / MAKE HIS NOMINEES PAY THEIR BACK TAXES.”

February 13th, 2009 at 7:08 PM

Remember that unless you intend to open a machine shop and run these things two or three shifts a day, six days a week, you’re not going to be able to put measurable wear on them in two or three lifetimes by yourself. A DRO is one of the happiest accessories you can have on a mill. Counting turns, and remembering how many thousandths you wanted to move the cut is a royal PIA. A DRO does that for you, and much more accurately to boot.

Gerry N.

February 13th, 2009 at 8:04 PM

All nice pictures.

The ways of a mill are underneath. The top surface that you see is the bed, or table. There are “dogs” that allow you to adjust the table, but they do tend to wear in the zone where they are most used. Leadscrew backlash is measured with a dial indicator, and you need to take the make-up out of the handle ends to do that. otherwise, you”re measuring the slack in the dials and not the leadscrew.

A new leadscrew for a bridgeport is not horribly expensive- but if you’re hardcore, you just buy threaded rod and turn the ends on your lathe, and make a new leadscrew.

I’m glad you’ve found a local place where you can put your hands on these things. It’s easier to decide what you want. And the millrite is a fine machine.

A DRO, even an old one, might work for a week, and might work for a hundred years. They’re surprisingly resilitent if they don’t get bent or hammered.

February 13th, 2009 at 11:07 PM

“Once I have a mill and a lathe, I should be able to consider my shop fundamentally complete.” What about your foundry and forge? Until you can work hot metal, your life will be incomplete.

February 14th, 2009 at 5:30 AM

And if you have a DRO, leadscrew backlash is not a concern as long as you remember to lock that axis when moving the other, or the table could “jump” and take up the backlash during a cut. If it comes to a choice: leadscrew backlash vs DRO, DRO wins.

February 16th, 2009 at 11:40 PM

Its great to see you having so much fun.

April 8th, 2009 at 4:16 PM

If anyone is interested I have a Millrite Powermatic Vertical Mill in excellent condition for $1150. Email me at shezzie00@aol.com Thank you.