A Sense of Proportion is no Vise

December 29th, 2009Rube Goldberg Drills a Hole

I think it is just barely possible that I ordered the wrong drill press vise.

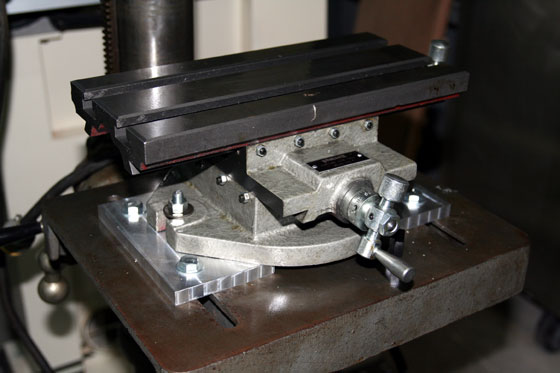

Here is my cross slide table, which I finally installed today. I had to make those slabs of aluminum from a 4″ square bar. Then I roasted a new countersink trying to make holes for the bolts that attach to the sides of the table. Apparently 1000 RPM, while fine for a 1/2″ 2-flute end mill, is not a great speed for a zero-flute countersink. Fortunately, there was a bigger one in the set, which I did not roast.

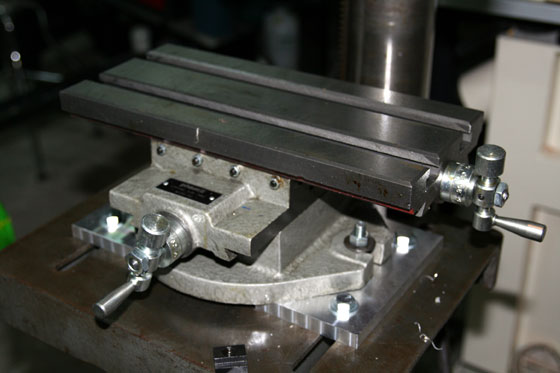

Here is my ancient Home Depot drill press vise, which probably has 2 1/2″ jaws. It’s too small.

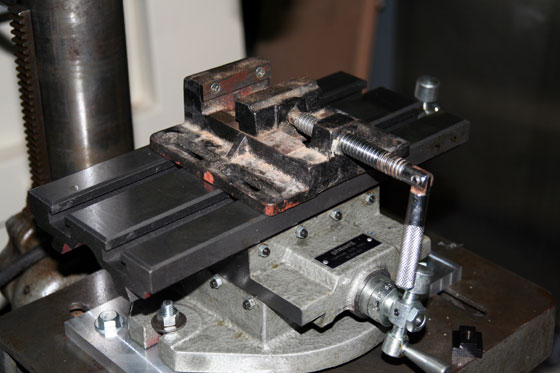

I figured 4″ would be about right. But check this out:

I guess I can make it work, but it looks a lot like the Grinch’s sleigh on the way up Mount Crumpet.

Maybe I should see about a 3″ vise.

I’m very pleased with the mounting job. It was not easy. I had to saw the slabs out. Then I had to mill them to size. After that, I had to drill the holes, and then I had to do the countersinking. I had to go to the hardware store to find bolts and stuff that would work. The cross slide table is designed as though the engineer who created it knew someone would try to put it on this type of drill press, and he was determined to stop them. I had to sink bolts into the aluminum slabs from below, because there was no way to go through the drill press table without cutting into it.

A more suitable base for the cross slide table would be a viable and useful project, but I’d need a big chunk of steel, and if I screwed up once, I’d have to trash it and start over.

The more I worked on this, the more I understood how much I needed a drill press. Drilling on the mill works extremely well, but you have to play around with a four-foot-long table and a gigantic vise. It would be much faster on the drill press.

I received a VFD for Christmas, so I’m going to slap a 3-phase motor on this puppy. I can’t live without reverse. I just can’t. You understand, right?

I feel like the king tool stud of the universe. And it will be nice to have this junk on the drill press table instead of scattered around the garage.

December 29th, 2009 at 8:57 PM

“I can’t live without reverse. I just can’t. You understand, right?”

I wonder if Teen Challenge can help with that.

December 30th, 2009 at 2:13 AM

Drill Presses are for drilling non precision holes.

Mills can be used for drilling medium precision holes.

Jig borers are used to drill/bore high precision holes.

December 30th, 2009 at 3:07 AM

Check out your books for the calculation of cutter speed based on tool diameter and RPM. They usually have it all reduced to a table based on the material you’re cutting. That will keep you from burning up your bits and cutters.