Shelf Improvement

September 5th, 2015Painting Isn’t for Everyone

I am sitting here waiting for paint to dry.

I have been struggling to get the garage workshop working, as you know if you keep up with the blog. I believe it’s a metaphor for my own inner transformation.

When you get involved with tools, you have to accept a bitter truth: before you can use the tools to do stuff to other things, you have to use tools to work on your tools to get them ready.

I guess it sounds discouraging, but there is no way around it.

There are a number of things you can buy at the hardware store and then use without preparation, but it’s surprising how many things don’t work until you fix them up.

Consider chisels. You can buy a set of perfectly good ones today at Home Depot, but they won’t be sharp enough to use. Also, Home Depot doesn’t sell the tools you will need to sharpen them. Can you believe that? What could be simpler than a chisel? You would think they would be plug-and-play.

To sharpen a chisel, you need some kind of abrasive tool, and you need at least three levels of grit. You can use a bench grinder to do the rough sharpening, if you’re highly skilled. Then you have to go to a water stone or a diamond stone. Then you have to go to a stone with a grit rating somewhere above 4000.

In order for a Home Depot chisel to be considered ready to use, it has to be able to pop tiny hairs off of you, just like a razor.

I don’t know why Home Depot doesn’t sell decent sharpening tools. Probably because the average chisel user does very crude work.

I have lots of tools, but I haven’t been able to use them as much as I wanted to, because I didn’t prepare them or myself. So now I’m working on it.

On a spiritual level, I’m doing the same thing to myself.

People love to say that Jesus said, “Judge not,” meaning, “Never criticize anything anyone else does.” That’s not true. What he really said was that we should judge ourselves first, and he made it clear that once we did that, we were supposed to judge others so they could benefit from our advice. He didn’t say we should take the logs out of our own eyes and then go home. He said that when we took the logs out of our own eyes, we would then be able to help others take the splinters out of their eyes.

When you beg God for correction and humility, you’re taking the logs out of your eyes.

You shouldn’t expect things to go all that well until you begin accepting correction. Before God straightens you out, you will be led by the flesh, not the Spirit. You will not want to do God’s will. You’ll want to do whatever Satan tells your flesh to do. You will not have the spiritual fruit of self-control. So God will not have much interest in helping you. It would be enablement.

As you accept correction, the spirits that have controlled you your entire life will lose their power, and the Holy Spirit will gain ground inside you. Then you’ll start to have strength and success, because you’ll be doing things God supports.

Prayer in tongues is a constant flow of correction, so it’s vital. We are surrounded by stupid voices all day, every day. Prayer in tongues is God’s answer to that.

One of my shop problems is a lack of provision for lathe tool storage. I have a bunch of heavy lathe tool holders, plus two huge chucks. I also have Allen wrenches and other junk. I need to have this stuff near the lathe, and I need it to be handy, but tossing it on top of the headstock and dumping it on the table saw extension have turned out to be poor solutions to the problem.

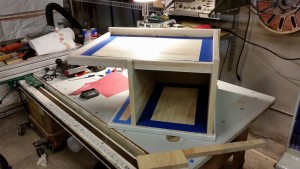

I knew that other people had created extended wooden shelves to enlarge the tops of their headstocks. I decided to create a box with a shelf on top. The box would hold whichever chuck I was not using, and tools would go on the top shelf.

You can’t imagine the nightmare that began when I started work on this.

First of all, the thing needed to be about 17″ long in the shortest dimension. Trees are very skinny these days, so you can’t just walk into a store and ask for a board 3/4″ thick and 17″ or more wide. You have to use plywood, which looks crappy, or you have to make your own boards. Like an idiot, I chose the latter route.

To make a wide board, you have to take two narrow boards and glue them together side by side. This is more complicated than it sounds. You have to use a jointer on the edges that mate. Then you have to use a hand plane to put slight indentations on those edges, to create a spring joint.

A spring joint is what you get when you put glue on two concave surfaces and clamp them together forcefully so they touch. You remove a few thousandths of an inch from the edges of two boards before you glue them up. You can’t even see the concavity.

When I made my first board, I did not understand the purpose of spring joints, but now I get it. If you have two boards that aren’t concave, when you push them together, you may get a gap at one or both ends. It will be a tiny gap, but it will show up when you sand and paint the wood. If you make a spring joint, the boards will touch at the ends, so you won’t get gaps there.

It took me days to make enough boards for the shelf thing. I guess the reason is that I don’t have a lot of clamps. I would use three long clamps to make a board, and while it set up, I would be idle, because I couldn’t clamp a second board together.

Once the boards were made, I had to use planes and a scraper to get rid of the microscopic lines where the boards came together. I learned a great deal about plane marks.

When the boards were made, I had to use the table saw to cut them to size, and then I had to use a shooting board and a plane to make them truly square. In the process, I found out that my Incra table saw miter gauge was not square, so I had to fix that.

After all of that, I had to do some routing. I needed tongues and dadoes to fasten the boards together. My mistakes drove me nuts.

For one thing, a router bit in a router table will push wood away from your router fence if you push the wood from left to right. I did not know that. I thought that if I used a little force to hold the wood against the fence, I would be fine. That was totally wrong. The boards would move away from the fence a sixteenth or so, opening up the dadoes. It was infuriating.

Thank God, I was making the dadoes narrower than the boards that went in them. This makes the joints harder to see. That meant the big router gouges were covered when the boards went into the dadoes. But it was still annoying.

I also learned that you have to plan the way the grain of your boards runs when you design your piece. If you have end grain against long grain, you can’t glue it, because the end grain will suck up all the glue. It’s okay for joints that don’t receive stress, but other joints will require some sort of joinery, such as dadoes, to provide new gluing surfaces where long grain meets long grain.

I learned that soft wood is horrible. It’s harder to work than hardwood.

If you use a chisel on hardwood, it will cut it cleanly. If you use a chisel on softwood, going across the grain, the wood may compress and tear instead of cutting. It’s like using a bread knife to cut a stack of Kleenex.

If you use a router bit in hardwood, it leaves a clean edge behind. In softwood, you may get a furry edge that needs to be sanded a lot.

Scrapers, which are incredibly useful, don’t work very well on softwood. That’s annoying, because they’re great for cleaning up glue lines and erasing plane scratches.

You also have to be careful about making grooves, slots, and dadoes in softwood, because if you get too close to the edge of a board, you will have a very thin wall of softwood on the outboard side, and it won’t support your tongue very well. Also, the router may kick the wood completely out when you’re making the dado.

I learned that poplar is stupid.

Poplar is a hardwood, but it’s not hard. It’s not a softwood, but it’s a soft wood. It’s about like pine in its consistency. I used some in the shelf because I thought it was the cheapest hard wood available, but it turned out to be a bad buy. It’s more expensive than pine, and it’s actually softer than the better pine grades. It’s very ugly, so it has to be painted. And it has all the problems pine has when you start trying to shape it.

I’m not sure what poplar is good for, but you can get clear pine for the same price, and it looks better.

It took me forever to get the shelf together, and then I had to deal with painting it. That’s where I am right now.

I wanted to use a tough blue paint that would shed oil. I decided to go with oil-based Rust-Oleum. I really wanted to do it right. But it looks pretty bad right now.

First of all, even though the primer I used is supposed to work fine with oil-based paint, there are little places where the paint just does not want to stick. I’m going to have to give it like 10 coats in those areas. Second, this paint is the farthest thing from self-leveling. It leaves huge ripples behind, and sanding doesn’t seem to budge them. Third, it drips like crazy.

I’ve also had problems trying to get up to speed with the art of painting, itself.

I’ve never been able to get a grip on cleaning brushes. I’ve generally thrown them out. The paint always goes way up under the ferrule, and you can never get all of it out. It takes a huge amount of thinner to clean a brush, and it’s a pain to deal with.

I got some instruction. It turns out you’re supposed to prepare a brush for painting by soaking it in mineral spirits. This goes up under the ferrule and takes the space paint would otherwise occupy. It will keep the paint from going up there and hardening. I can’t believe I got this old and didn’t know that. No one told me! And you can look at websites all day and never see this information.

I found a video that explained it, but the guy in the video took the brush straight from the mineral spirits to a container of varnish and started painting. I had to ask about that. Obviously, it’s wrong, because the thinner on the brush will thin the paint you’re trying to apply. So you have to get the excess thinner off the bristles. Something he should have mentioned, right?

No wonder people consider brushes disposable.

I have been working on the paint for days, and it’s still not done. I finally decided to settle for a garage-grade finish. Maybe once the shop is working properly, I can make a new shelf. But I have to get this thing done and use it, or I will lose my mind.

I would really like to do things right, but I’m going to have to start accepting my limitations. Once in a while, “okay” will have to be an acceptable substitute for “perfect but unattainable.”

In other news, my new old church is getting weirder.

They have a prayer line. I used to be part of the prayer team. They’re supposed to call a conference line three times a week and pray for the church and so on.

I quit the team months ago. I felt like they were praying in an ineffective way, without solid guidance from the Holy Spirit. You’re not supposed to pray for two seconds for everyone on earth. You’re supposed to let the Holy Spirit choose your battles. You pray for the things he tells you to pray for, the way he wants you to do it. They were taking kind of a shotgun approach. Also, most people weren’t showing up. Usually there were only three people on the line. The pastors and the “house prophet” didn’t participate regularly, which makes you wonder what the pastors were being paid to do.

A lot of people wonder what the pastors are being paid to do. The impression many people have is that during the week they do absolutely nothing but go to the spa, travel, and visit restaurants.

I didn’t say anything critical when I left the prayer line. I just quit and said I felt like I should be doing something else.

I have a friend from the Panhandle, and she has been very good to the church. Although she wasn’t a member, she helped them financially and drove down to visit from time to time, and she was a hard core prayer line warrior.

Last week, the pastor’s wife changed the prayer line number and didn’t give it to her. Something about wanting to confine participation to church members. To be clear, she was deliberately cut out.

You have to realize, this woman was not my puppet. She wasn’t calling the prayer line and telling them how bad the pastors were for rejecting me. She was just praying. But now she’s out.

They cut another person out. She’s a young woman with some type of mental retardation. I don’t know what the proper name is. It’s not Down Syndrome. She’s very sweet, and she is a very sincere Christian. She has visions. She sees angels. She wanted to be on the church’s dance team, but they wouldn’t allow her to perform. I don’t know why. It’s not the Bolshoi Ballet. It should not be hard to qualify. If you’re not good enough to dance for God, at a tiny church which is currently failing, where, exactly, can you expect to be accepted? You can’t shoot any lower.

She and her mother eventually left the church. But the young woman continued with the prayer team. Sometimes she was one of only two people who called in. Now she’s out!

How a preacher can want FEWER people to pray for a church is beyond me. That’s a new one in my experience. The church is sinking. They are losing dedicated people. Their planned moves to bigger buildings got squashed. The air conditioning in the tiny room where they meet is out, and knowing the landlords, it may be another two weeks before it works again. It appears that their orphanage in Haiti has gone nowhere. The prayer team is nearly gone. Is this really the time to ramp up the ostracism?

I don’t know what to think about it, but I’m glad I got pulled out.

My plan for my own life is to keep asking for correction. It’s working beautifully. It makes life easier, except for painting. It’s what we all need. It’s what Jesus died for.

I can’t do anything for people who are convinced they’re already perfect. If God’s methods of improving people involved grabbing them against their will, opening them up, and replacing parts, it would be easy to help others, but unfortunately, most of it relies on their willingness to listen.

As for me and the people close to me, we keep getting new revelation, and things keep improving. I feel better. I have more success. I worry less. Doors are opening so I can get out of Miami.

I have learned that when there is an area where I fail consistently, God is trying to teach me a lesson, and when I finally learn it, he will let me move forward and succeed. This is what happened to the Hebrews under Moses. They walked in circles and died in the desert, but the ones who had not rejected God’s counsel were allowed into the Promised Land.

I still have no interest in joining a new church. Maybe some day.

If I get this crazy shelf put together, I’ll put up a photo. I can’t wait to see it on top of the lathe, with all my junk stuffed into it.

September 5th, 2015 at 11:53 PM

A guy in a hardware store once told me that they didn’t sell really (read *properly*) sharp “every day” chisels because, unlike knives, people didn’t appreciate the extra effort.

Honestly, I’m not sure how accurate that is, but in a way it does make sense. I think the biggest reason is that most people seldom need their chisels quite that sharp. I have about 8 different stones to sharpen my chisels and can count on both hands the number of times I needed to get one sharp enough to use the top three stones. I spent four solid months sharpening/polishing my Katana Sword from WWII, and that ended using 12,000 grit for the final polish.

You’re so right. Poplar sucks. Even though it is reputed to hold paint better than almost any other wood, for me, that’s not worth the trouble of working with it to get it to the point of painting.

It’s funny, you’re working wood and I’ve been working on a chainsaw. Just added a 24″ bar to my Husquvarna 359–and had to take apart the clutch to fix a jammed chain tensioner. Once the bar was on, you have to spend about 30 minutes breaking in the new chain and bar (if you want to get your 100 bucks worth out of it). Also just got a standing lift machine for my lawnmower and golf cart. I can now change/sharpen the blades and change tires/work on engines without squatting down and trying to balance a jack in the right spot or use ramps that keep getting in the way.

You’ve GOT to get up here soon and hang out in the shop for a while. With two of us in the same shop building, the world would be a better place once we got finished. You’ve been on my mind lately and have been praying for you.

Oh, and Benny Hinn says, “Hi!” and wants you to call him when you get a chance. He has a word for you.

September 6th, 2015 at 11:03 AM

Did DOCTOR Hinn quote a price, or was it the usual, “If you have anything left, you are a sinner”?

September 7th, 2015 at 12:25 AM

*snicker*

Come to think of it, it might have been Benny Hill. I do often get the two of them confused. After all, both their shows are a running joke and the music sounds like a bad carnival.