Ready to Rock

June 9th, 2011Yeah, Dawg

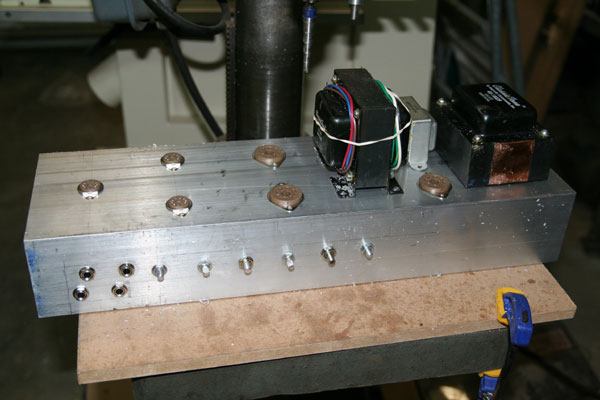

The hard work on my amp is all done. From here on out, it’s small strokes. Here’s what I got:

There are two hollowed-out places behind the front panel now. The first one is where I put all the stuff you see now. The other one will make it easier to mount switches and a light, although it really isn’t needed, since switches have long threads and the light has a long housing.

I may forgo a cabinet. I’m very tempted to turn this into an industrial-looking all-metal amp. Not steampunk, but closer to that than Fender. I would need to come up with a nice-looking cage to go over the top and protect the tubes. Hey…I wonder if I could fill copper tubing with epoxy, bend it to a suitable shape, and let it harden. By itself, copper is too flimsy. Although I suppose pipe might work. I have things for bending tubing.

I can’t wait to fire it up and see if it explodes. Maybe tomorrow. I won’t have knobs by then, however. Unless I go with Radio Shack.

I need a reasonably priced tool to check capacitances. I don’t know why, but capacitors are marked in ways nobody can read. My Fluke meter only goes down to nanofarads. I have a whole drawer full of capacitors, and I can’t read them. Even the Internet is useless.

I don’t know what I’ll do with a 30-watt amp. Put my speaker cabinet in an isolation box, maybe. My speaker is only rated at 25 watts, though.

I am loving this project.

And now I think I’ll embed a stupid commercial because it cracks me up.

Someone please tell me what a bro-stache is.

No, don’t.

June 9th, 2011 at 9:13 PM

I don’t consider them reasonably-priced, but these Smart Tweezers aren’t bad (http://www.advancedevices.com/Smart_Tweezers_LCR_Meter.htm). They actually work pretty well in-circuit, but I’m not sure how well they do at pF capacitance levels. (Reviewed here http://www.youtube.com/watch?v=rNmZ1JC2jkY&feature=list_related&playnext=1&list=SP195AB0E12CE8BB8F, if you can take the accent/voice.)

I’ve seen this one recommended as well: http://www.aade.com/lcmeter.htm, but have never used it. And if you’re interested in yet another project: http://electronics-diy.com/lc_meter.php

June 10th, 2011 at 5:51 PM

Build a 1″x1″ aluminum angle perimeter framework (TIG welded or bolted) and cover it with some funky perforated or expanded metal from here:

http://www.mcnichols.com/products/perforated/

You could even put in additional sub structure across the middle to have a suitcase style handle on the top.

(also consider self tapping sheet metal screws run into precision located 1/16″ pilot holes pre- drilled for all of the fasterners instead of wood screws.)

June 10th, 2011 at 6:11 PM

That perforated stuff looks good.

.

I hate to admit this, but I don’t really know the difference between wood screws and sheet metal screws. They look the same to me. For all I know, I have sheet metal screws in it right now.

.

As for precision drilling, I’ve found that the only way to get accurate holes is to use the mill. Even the drill press wanders. And my Chinese center drills…I’m ready to throw them out. Useless. I have some better ones, but I don’t want to take them out and get them dull until I have to.

June 11th, 2011 at 3:56 AM

When I said “precision” I actually mean located with a scribe or .5 mm pencil or other marker and a ruler, center punched, and drilled thru with a hand drill.

.

The “drill screws” would be something like these:

.

http://www.stainless-fasteners.com/sdapplications.htm

.

and would follow the little pilot holes you laid out by hand (Home Depot stocks some some similar variety.)

.

If you are using thin steel or aluminum sheet the “wood screws” will work but for connecting to that thick channel you will end up twisting off and breaking standard crappy galvanized A-307 screws when you get half way in.

.

If you don’t need a whole 4′ x 8′ sheet of expanded/perforated metal from McNichols I think that Lowes and Home Depot and even McMaster Carr has smaller portions but in the end you probably save money getting a whole sheet and paying the freight and saving the left over scrap for future projects.

.

If you lay things out right you can minimize waste and have grills for the speaker cabinet(s) you are going to want to build for your PA system as yet not dreamed of.

.

PS…McNichols will shear a full sheet of metal to your actual needed size or at least in half to make it easier to deliver also.